Lizhu machinery is a manufacturer specializing in high-speed and precision vertical injection molding machines. It established an R & D and production base in Suzhou in 2011, sold globally, and established more than 10 sales and service bases abroad.

Lizhu machinery is a manufacturer specializing in high-speed and precision vertical injection molding machines. It established an R & D and production base in Suzhou in 2011, sold globally, and established more than 10 sales and service bases abroad.

Lizhu machinery is a manufacturer specializing in high-speed and precision vertical injection molding machines. It established an R & D and production base in Suzhou in 2011, sold globally, and established more than 10 sales and service bases abroad.

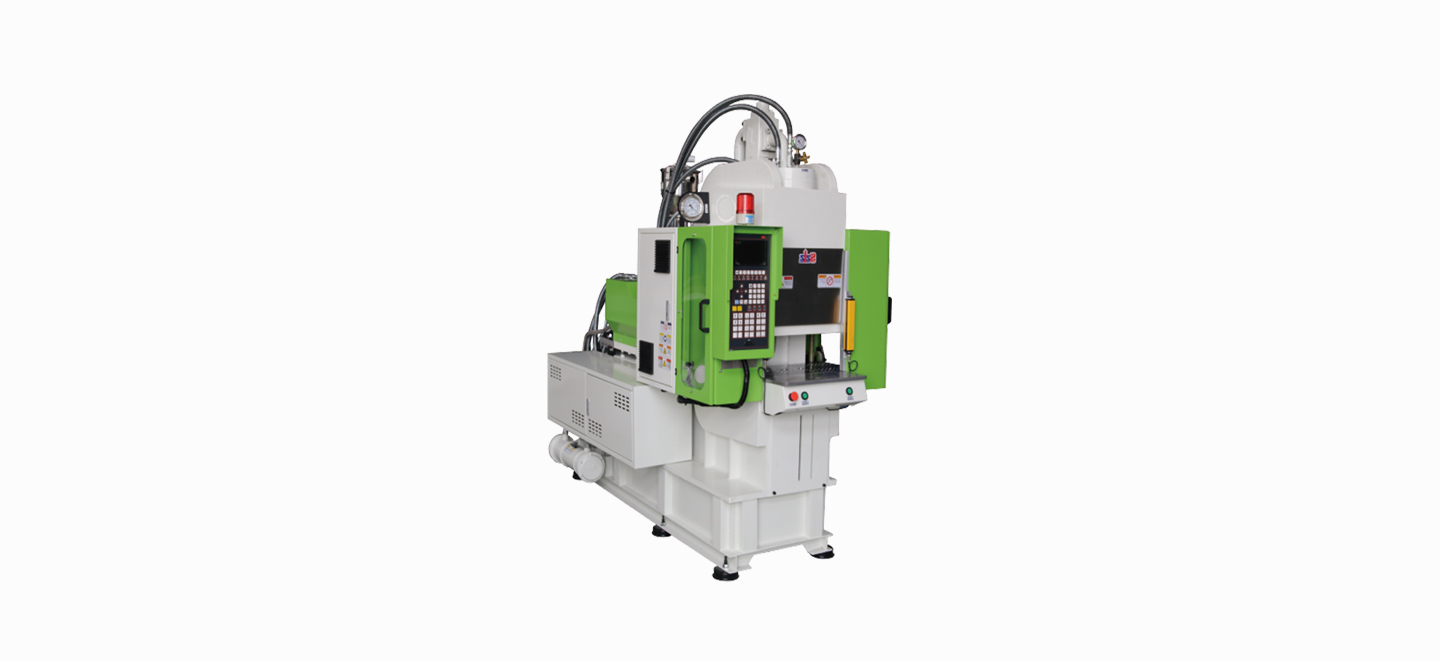

Vertical clamping and horizontal injection with a C-type structure, this series of injection molding machines is suitable for producing products with embedded components, such as electronic components, automotive parts, medical accessories, and aerospace parts.

Clamping force: 45-75 tons

Injection volume: 0-300 grams

The C-type structure without tie bar makes it suitable for producing products with wire connectors and sealing connection.

Product options include a double slide plate, rotary table system, and a servo energy-saving system. The options for a double slide plate, rotary table system, and servo energy-saving system provide additional customization options for the machine.

Telephone Consultation

Wechat Consulting

Online Message