Lizhu machinery is a manufacturer specializing in high-speed and precision vertical injection molding machines. It established an R & D and production base in Suzhou in 2011, sold globally, and established more than 10 sales and service bases abroad.

Lizhu machinery is a manufacturer specializing in high-speed and precision vertical injection molding machines. It established an R & D and production base in Suzhou in 2011, sold globally, and established more than 10 sales and service bases abroad.

Lizhu machinery is a manufacturer specializing in high-speed and precision vertical injection molding machines. It established an R & D and production base in Suzhou in 2011, sold globally, and established more than 10 sales and service bases abroad.

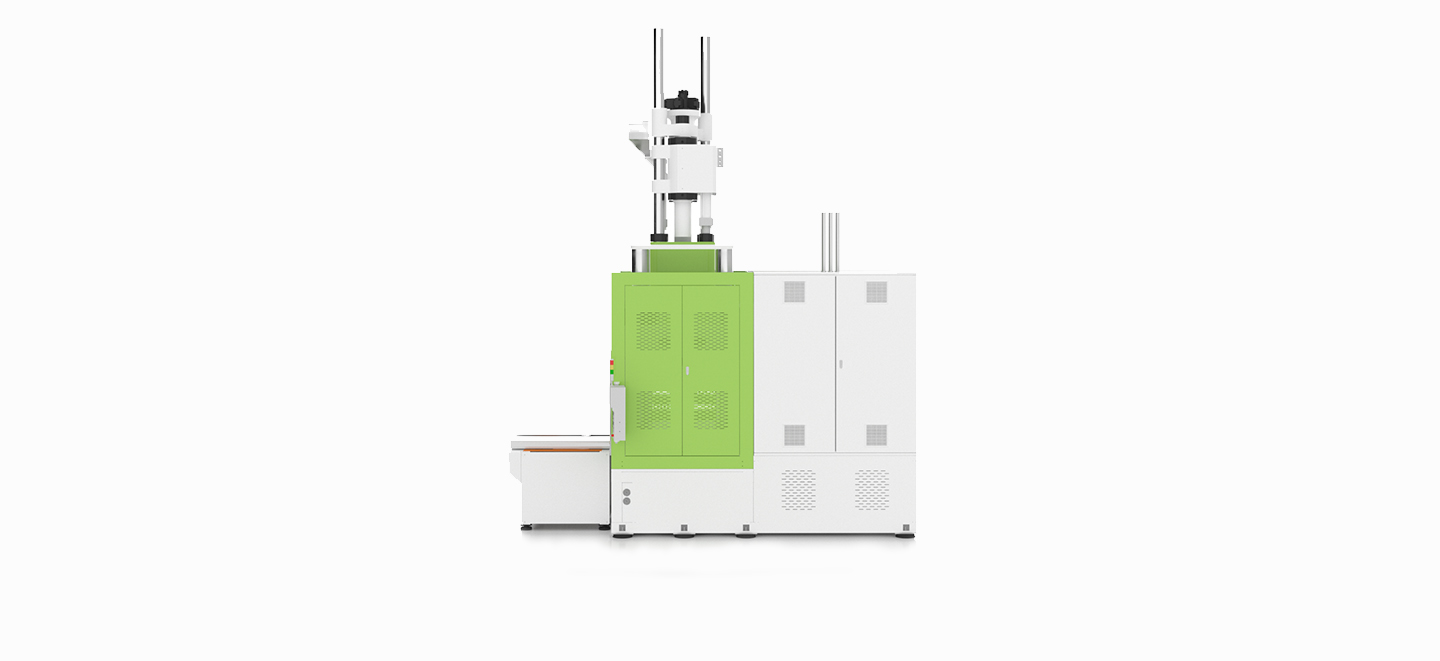

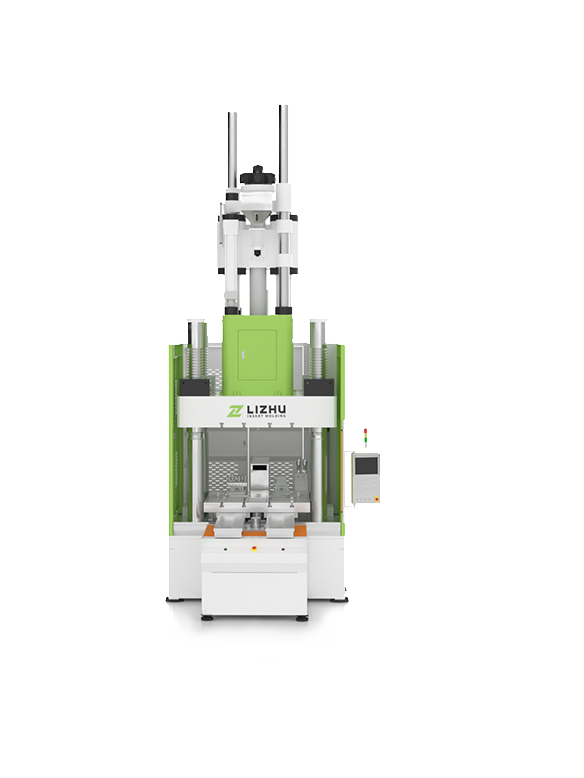

Vertical clamping and vertical injection, this low-position two-plate machine is designed to accommodate various sizes of molds with stable balance and avoid lock force loss.

Clamping force: 160-2000 tons

Injection volume: 0-6000 grams

Mold size: 2500*2500mm

The machine features a mechanical brake lock system that can adapt to molds of different sizes and provide a stable balance, avoiding lock force loss. It has reduced the design of large oil cylinders, effectively improving the low-pressure mold protection function and reducing the self-weight of the machine.

The clamping unit and injection unit are installed in an overlapping manner to reduce the overall height, and all the tonnage operations are controlled at a height of 800mm.

Product options include a single slide plate, double slide plate, and rotary table. Function options include an independent top pin system, servo energy-saving system, electric injection system, and high-speed injection system.

It is suitable for producing products such as automotive glass sunroofs, battery housings, large copper terminal blocks, automotive shields, and large automotive functional parts.

Telephone Consultation

Wechat Consulting

Online Message